Designing Operational Processes for a Mining Client

Applying design methodology to visualize workflows, user touchpoints, and pain points

The Problem

Process inefficiencies were frustrating for users and costing millions of dollars.

The client is a leading Canadian company in the mining industry with operations internationally. They had recently undergone a site-wide system implementation which did not fully meet user or business needs. There was confusion around how processes should be done, who was responsible for what, and whether the data in the system was to be trusted. These gaps were causing operational inefficiencies, lack of visibility into inventory, and significant financial impacts.

How might we help the client gain confidence in their business processes while identifying opportunities for cost savings?

The Solution

We clarified 10 current state processes and co-designed 2 future state processes.

We designed and documented the client’s warehouse and inventory management processes to improve operational efficiency, visibility, and user confidence through talking to stakeholders, collecting their pain points, and co-creating processes that would work for them.

The project delivered:

End-to-end mapping of warehouse and inventory processes to surface user and system pain points

A future-state model for Returns and Obsolescence, including governance and role clarity

Data-informed inventory optimization to reduce waste and improve decision-making

Stakeholder-aligned recommendations for ongoing service improvement

My role:

Developed and refined process maps for 12 warehouse and inventory workflows

Gathered stakeholder insights through workshops and user interviews to identify pain points

Co-designed the Returns and Obsolescence model and governance structure

Secured leadership alignment and ensured the service model was actionable

Through this project, the client gained visibility into their warehousing and inventory management processes with opportunities to address critical pain points. Our work consisted of the following phases:

Problem Definition

Current process accountabilities and workflows were unclear.

To familiarize myself with the client's existing ecosystem, I gathered as much data as possible from our client stakeholders and reviewed all documented pain points, root causes, and recommendations from a previous phase of work.

Through preliminary background research, I identified that:

There was no documentation of the end-to-end flow of activities to identify how each process connects to other processes and the various teams involved.

Existing process documentation was out of date and did not contain enough detail.

There were 12 key processes in the Warehousing and Inventory Management space that required detailed documentation.

Stakeholder Identification

Materials Handlers and Inventory Analysts were our main user groups.

To get a deeper understanding of the client's business operations, the team and I took a two-week trip to the client's primary mine site in Western Canada to conduct user interviews and observations on how day-to-day tasks were being performed, mapping day-to-day workflows and identifying how users interacted with systems, tools, and each other. Additionally, we met with key stakeholders to review and refine each process.

Our core stakeholders included both executive leadership, who defined the project’s success metrics and strategic outcomes, and the frontline users who interacted with the processes daily—namely warehouse Materials Handlers, Inventory Analysts, and their supervisors and managers. In addition, we considered the upstream and downstream impacts of each warehouse process, which expanded our indirect stakeholder group to include teams such as Sourcing, Finance, and IT, among others.

Our full stakeholder map is shown below:

As we engaged our stakeholders through interviews, it was apparent that the lack of standardized processes was leading to complete distrust in system data, creating a vicious cycle of inconsistencies and confusion for all warehouse staff.

To better understand and empathize with our stakeholders, I created personas for the two primary roles that we worked with: Materials Handlers and Inventory Analysts.

User Research

User interviews revealed challenges involving people, processes, technology, and data.

The goal of our research was to understand the end-to-end warehouse and inventory processes, uncover pain points, and identify opportunities to standardize processes and improve operational efficiency.

We collected information in the following ways:

Interviews: Conducted on-site interviews with materials handlers, inventory analysts, supervisors, and managers to capture firsthand experiences.

Observation: Walked through warehouse and mine-site areas to observe how work is actually performed, including physical and digital interactions.

Process walkthroughs: Reviewed workflows step by step to understand dependencies, handoffs, and technology use while asking stakeholders to describe workarounds and frustrations, capturing both inefficiencies and hidden knowledge.

Through our research, we uncovered 55 distinct pain points across the warehouse and inventory management processes and grouped them into four categories: People, Process, Technology, and Data. I used an Excel spreadsheet to track these pain points along with their prioritization and possible solutions.

This analysis allowed us to identify the root causes of inefficiencies and informed the following key insights:

Insight #1

Lack of Standardization Leads to Confusion

Many employees were unclear about their responsibilities and were never taught the right way to perform important tasks.

Items would not be scanned in or out of the system correctly due to confusion about where it is going. It may then be put into a pile in the corner and forgotten.

Insight #2

System Data Is Unreliable Due to Improper Execution

Incorrect or missing scans and inconsistent system use made inventory data inaccurate, reducing trust and slowing decision-making elsewhere in the supply chain.

Inventory Analysts would know about the unscanned items in the warehouse but have difficulty validating the POs or quantities.

Insight #3

Poor Process Control Results in Financial Loss

Without standardized ordering limits or clear inventory accountability, employees would over-order out of fear an item might run out faster than expected or get lost in the chaos.

Due to this practice, excess stock accumulated, resulting in millions of wasted capital over time.

Re-Design

Frameworks to clarify touchpoints and accountabilities were defined.

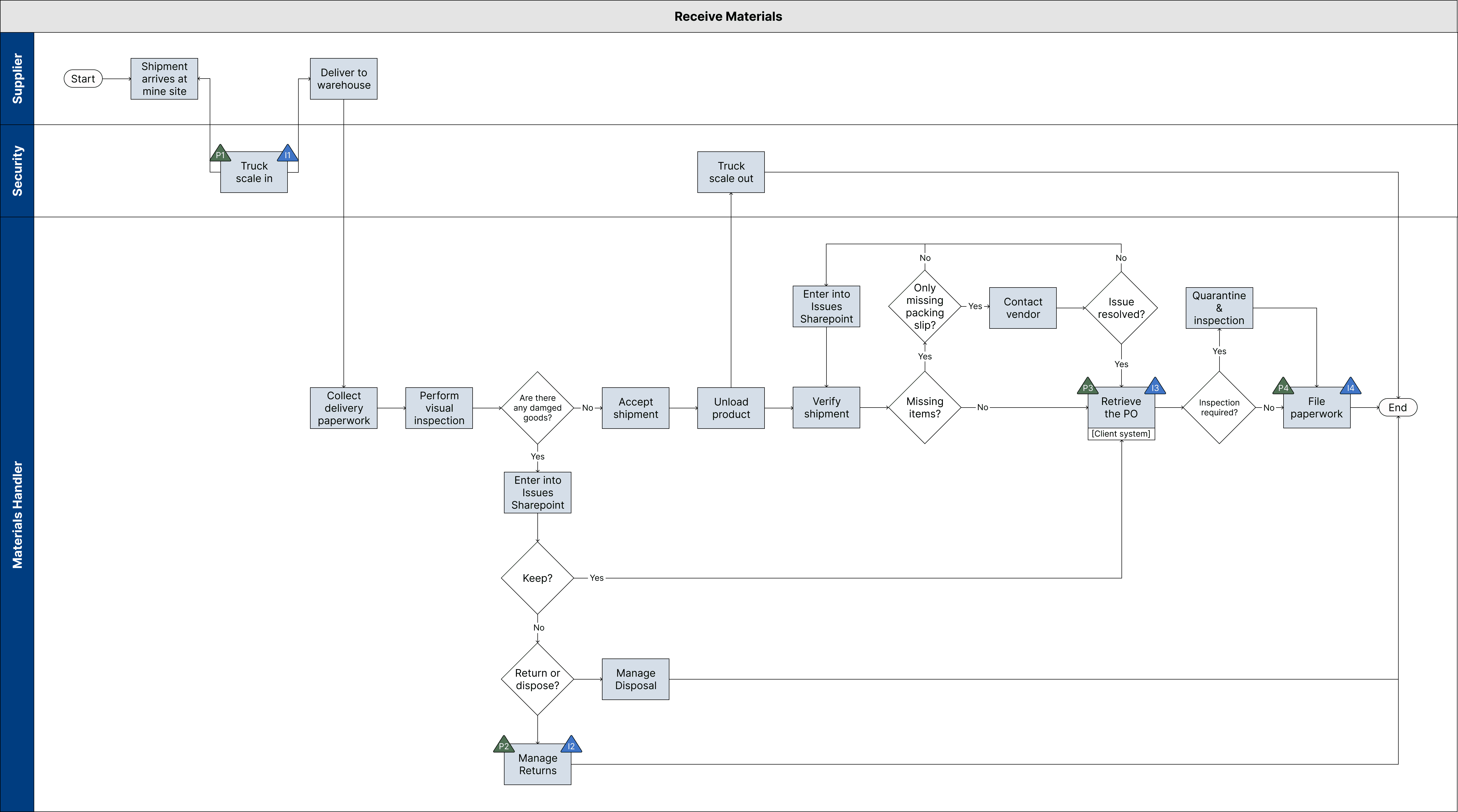

To translate research insights into actionable service improvements, I developed detailed process maps for 12 warehouse and inventory management workflows. These maps captured:

Touchpoints between users, systems, and operational processes

Pain points and inefficiencies identified during on-site research

Roles and responsibilities across teams

Opportunities for process improvement and automation

The mapping work enabled stakeholders to visualize the end-to-end journey, identify gaps in accountability, and standardize the processes across teams. These maps became a foundation for aligning cross-functional teams and driving operational improvements.

The process for "Receive Materials" is illustrated below:

Process Creation

We designed the future-state returns and obsolescence processes.

In addition to the numerous pain points from existing warehouse processes, proper management of inventory was a key challenge for the client. The lack of visibility into inventory levels combined with improper methods of ordering had caused roughly $10 million worth of unused materials to be ordered over the last year alone.

Through detailed analysis of the client's inventory, the team identified $13 million in inventory reduction savings through a process to manage obsolete items. Using cross-functional design workshops with Finance, Procurement, and Warehouse teams, I co-designed a future-state Returns and Obsolescence process to address key operational challenges.

The rapid service map below illustrates the end-to-end flow of materials, decisions, and accountability across Procurement, Warehouse, Maintenance, Accounts Payable, and the Supplier in the warranty returns process, providing a clear, standardized method to prevent excess inventory accumulation.

To support this new process, we:

Defined end-to-end workflows, roles, and responsibilities across teams

Established a governance structure to clarify decision-making and accountability

Aligned processes with both user needs and business objectives, including efficiency and cost-savings goals

Created an actionable RASCI matrix for leadership approval

Illustrative Partial RASCI Deliverable:

Recommendations

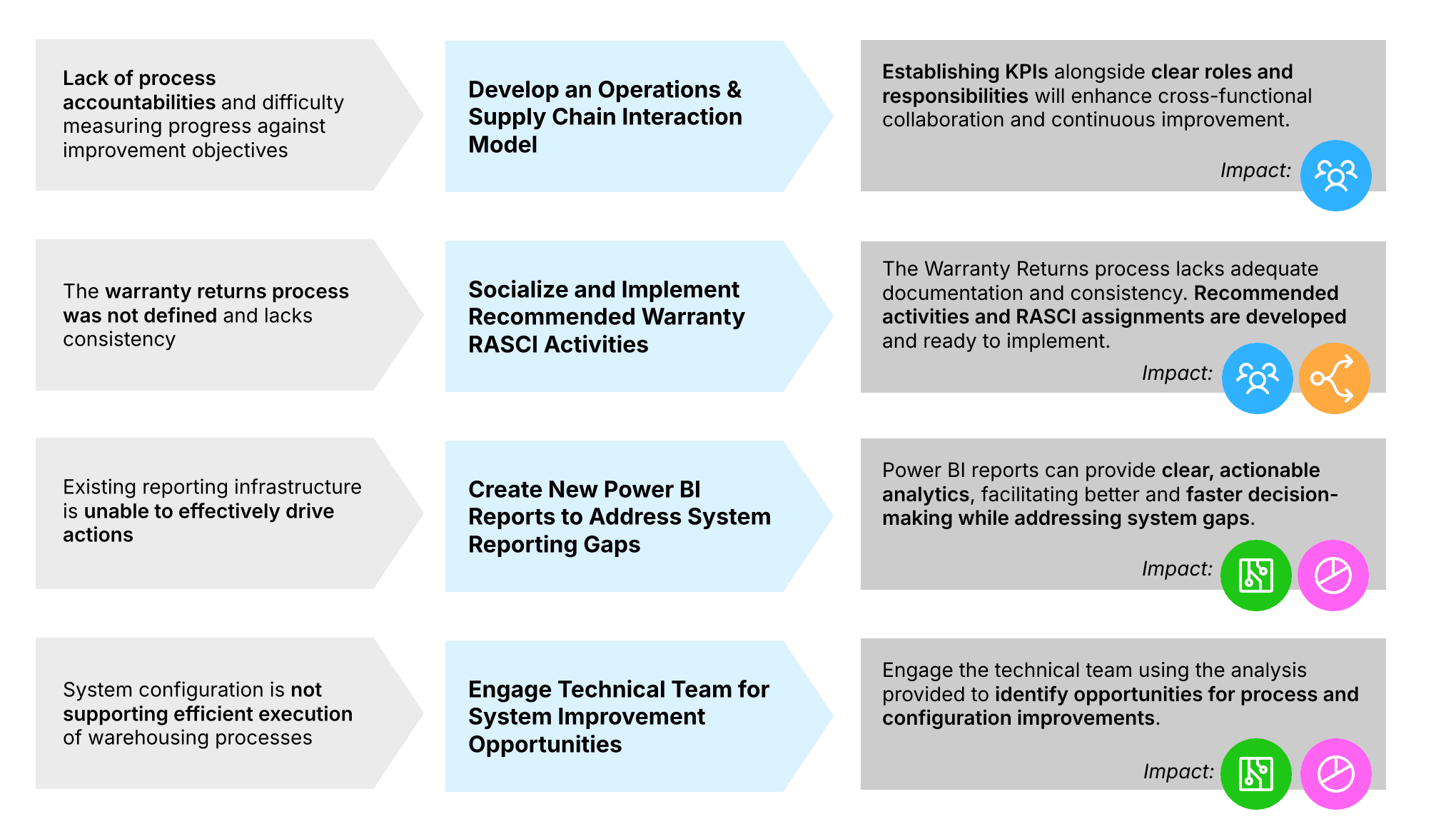

4 recommendations were provided to optimize system performance and user experience.

Upon finalizing the 12 process maps and further discussions with the client on their most critical pain points, we further proposed 4 key recommendations that addresses each of the 4 categories of user pain points:

Visual of recommendations

Next Steps

Alignment across the client's international mine sites.

Due to the success of this project and the deep understanding of the client's business operations obtained by the Accenture team, the client wanted us to continue with our learnings to further align processes across their Canadian and international mine sites.

The next phase of this project included preparation for and facilitation of a week-long in-person workshop in Vancouver consisting of 20+ stakeholders from various parts of the organization, including warehousing, inventory management, finance, and more to identify process gaps between mine sites and to develop a roadmap for closing these gaps while aligning with industry best practices.

Conclusion

Understanding the user is critical in designing sustainable systems.

This project highlighted the importance of user-centered, service-led thinking in understanding and improving complex operational systems. By engaging directly with stakeholders and observing day-to-day activities, we gained insight into the pain points, workarounds, and interactions that shaped the warehouse and inventory service. This empathetic approach allowed us to see beyond surface-level tolls or processes and understand the human experience within the service ecosystem.

Aligning these insights with organizational goals, operational constraints, and efficiency considerations, we were able to map the end-to-end service, visualize touchpoints, and clarify roles and responsibilities. This holistic understanding provided a strong foundation for identifying opportunities to streamline operations, enhance accountability, and improve user confidence.

The project reaffirmed that in complex systems, integrating service design methodologies, including stakeholder engagement, process mapping, and user-centered research, creates sustainable solutions that not only meet business objectives but also meaningfully improve the experience of everyone interacting with the service.